Class V (Ammunition) Distribution Management

With the recent publication of Army Techniques Publication (ATP) 4-42 Materiel Management, Supply, and Field Services Operations, November 2020. The Army has provided a holistic overview of supply support. While ammunition is another commodity in the supply system, munitions supply is a complex logistics operation due to the critical need during operations, inherent hazards of material handling, and the regulatory security requirement in its distribution. The ammunition supply commodity (Class V) includes all types of explosives, mines, pyrotechnics, missiles, rockets, propellants, and other associated items.

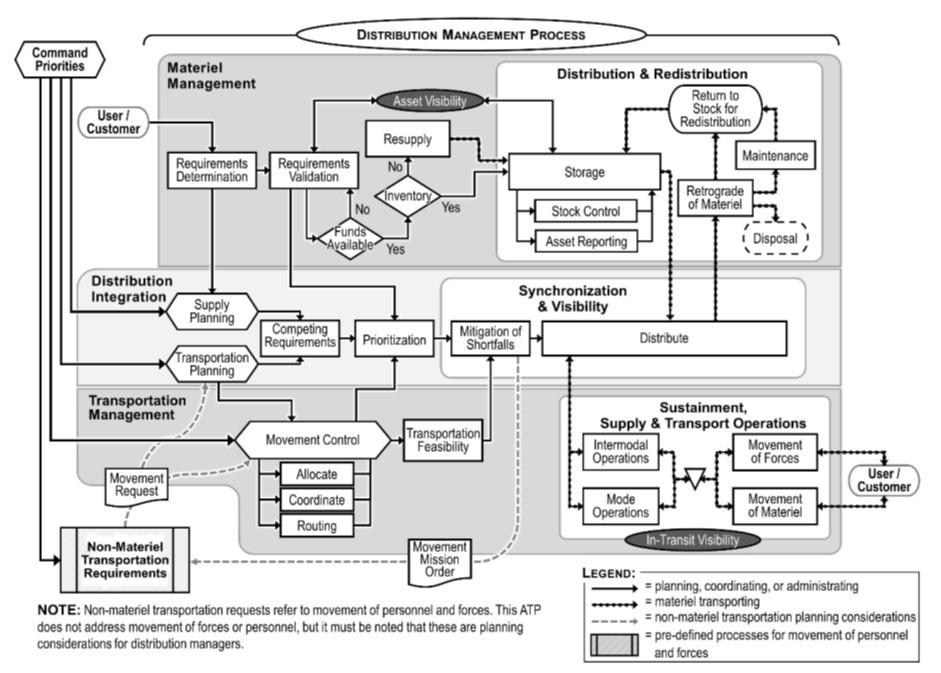

Distribution Management Process

Overall, ammunition supply support encompasses materiel and distribution managers from the industrial base, strategic and operational units, and the tactical level to optimize ammunition resources. Class V materiel managers execute supply support using the Army distribution management process that includes the following:

· Materiel Management,

· Distribution Integration, and

· Transportation Operations Functions.

While ammunition material managers will find themselves primarily in material management, they will need to understand distribution integration and transportation operations functions. Materiel management for ammunition encompasses end item acquisition, identifying requirements and selecting supply sources, overseeing other functions such as scheduling shipments, and ammunition receiving, storing, and issuing to units. Providing class V support to units can be a push system or pull system. A push of ammunition goes to the supported units, or supported units pull ammunition from ammunition support activities. Ammunition Material Management covers a wide array of functions.

Materiel Management

Army Techniques Publication 4-42 describes Materiel Management as the continuous situational understanding, planning, and execution of supply and maintenance capabilities to anticipate, synchronize, and direct all classes of supply to maximize combat power and enable freedom of action in accordance with the supported commander’s priorities.

Two of the least understood aspects of ammunition material management by service members are procurement and stock record accounts. The reason for lack of knowledge in these two areas is that the Army Civilian Workforce provides the capability through organizations at Headquarters Department of the Army, Army Material Command, and Logistics Readiness Centers. Procurement appropriations provide financial investment to cover the critical cost to supply end items. Procurement of Ammunition, Army (PAA) appropriations is for the construction, procurement, production, modification, and modernization of ammunition and accessories, including ammunition facilities. Class V supply entered the Army inventory through a stock record and returned to a stock record for maintenance, demilitarization, or disposal. Ammunition end items go to a stock record required to store material while awaiting an issue to a unit.

Materiel managers execute Class V supply support using the Army distribution management process. A fundamental understanding is required of Materiel Management and Distribution Integration and Transportation Operations Functions to ensure that operations meet the commander’s end state.

Figure 1. Distribution Management Process

To that end, there must be coordination between Class V Materiel and Distribution Managers in Sustainment Units and Staff Officers in Maneuver Units with the affected units and ammunition support activities to synchronize all the warfighting functions. Ammunition materiel management includes but not limited to the functions as follows:

· Supply planning, which includes establishing ammunition Stock Objectives at each support echelon.

· Requirements determination is developed by all activities based on their training and mission objectives through the Total Ammunition Management Information System (TAMIS).

· Requirements validation is the confirmation of requirements through the Munitions Requirements Distribution Plan (MRDP).

· Funds management is the managing of funds for Second Destination and ensuring the correct use of Department of Defense Authorization Account Codes (DODAAC), and control of ammunition authorizations.

· Resupply is obtaining ammunition supplies to meet operational requirements based on the U.S. Transportation Command (USTRANSCOM) availability and schedules.

· Retrograde is returning excess or unserviceable ammunition material.

· Disposal is the use of Explosives Ordnance Disposal (EOD) unit to dispose of uneconomically repairable or obsolete ammunition.

· Maintenance provides the upgrade or repair of items such as missile systems or artillery munitions.

· Storage provides the safeguarding of ammunition at supply points.

· Asset visibility is accomplished through the use of Radio Frequency Identification (RFID) tags and Radio Frequency –In transit Visibility (RF-ITV) Tracking Portal to provide the status of ammunition materiel.

· Stock control is maintaining proper location and identification of ammunition within storage locations.

· Asset reporting provides instant reporting of on-hand assets through the Standard Army Ammunition System (SAAS).

· Supply is the issuing of ammunition items to supported units.

Distribution Integration

Army Techniques Publication 4-42 defines distribution integration as aligning personnel, equipment, and materiel requiring distribution (in terms of commodity, quantity, and priority) with adequate transportation capabilities to synchronize distribution to support the concept of operations. While the distribution integration branch (DIB) develops the supported higher headquarters distribution plan, but the munitions’ expertise is in the material management branch. Although the DIB integrates the forecasted ammunition requirements and available transportation provided by the transportation operations branch, neither branch might have experience with ammunition operations’ complex logistics. Ultimately, the distribution integration branch is responsible for satisfying future requirements, prioritizing shortfalls, and identifying the shortfalls’ risk. These responsibilities may fall onto more experienced ammunition material managers. The following functions may be the bases for allocation decisions:

· Prioritization is determined by the command within the Class V commodity and by unit priority. Dictated by the mission, an example may include a priority of Infrared Red over standard illuminating rounds. Or Special Forces units may be a priority over conventional infantry battalions.

· Mitigation of shortfalls ensures transportation assets against an identified requirement deficiency. The transportation may include other options such as sling load or airdrop. However, with the increase of new technology, options may even include drone resupply.

· Synchronization ensures there is no backlog of ammunition in the transportation operation cycles as there are limits of net explosives weight (NEW) at nodes.

· Feasibility determines if ammunition can move from the point of origin to the final destination within the time required, including from the industrial base and prepositioned stocks.

· Distribution provides the logistics system to deliver the right amount of ammunition to the right location and time needed to support operations.

· Redistribution is the reallocation of ammunition within the theater using all transportation assets available, which may include other services, allied and partner nations.

· Visibility allows for the status of ammunition in the supply chain with allocated transportation and priority of movement.

Transportation Operations Functions

While the transportation operations branch develops the movement plan, the branch also assesses the transportation system by mode and the capabilities at each node. The mode executes movements using various conveyances (truck, lighterage, railcar, aircraft) to transport cargo or personnel. A node refers to a location in a mobility system where a movement requirement is originated, processed for onward movement, or terminated. Intermodal operations are the process of using multiple modes through entry points and the network of nodes. The capabilities at each node must include available transportation assets, loading and unloading capability, storage capability, and other factors affecting transportation services. Transportation management functions related to munitions include the following:

· Theater distribution includes the flow of ammunition material within the theater to meet the geographic combatant commander’s mission.

· Transportation planning is a logistics function that includes movement control and the associated activities of munitions.

· In transit, visibility is the ability to track ammunition from origin to either consignee or destination.

· Movement of forces is the movement of units within an operations area that would need to be supported by Ammunition Support Activities.

· Intermodal operations use multiple modes and conveyances through entry points and nodes for class V sustainment.

· Mode operations are ammunition movement using various conveyances, such as using flatbed trucks or railcar to the port of embarkation.

· Movement control allocates transportation assets and regulating movements of ammunition to synchronize actions.

The distribution management process is a complicated procedure, which involves data from multiple automated systems such as TAMIS, SAAS, and RF-ITV. The coordination among different sections within and outside of sustainment organizations must provide ammunition within a distribution plan. The distribution management plan must provide the right amount of ammunition required to sustain large-scale combat operations and follow on resupply to ensure successful mission accomplishment. Each function depicted in the flowchart below must integrate seamlessly together to guarantee ammunition is available to supported units.

Figure 2. Distribution management process flowchart

Conclusion

Ammunition expertise must extend past material management, and individuals must be self-aware of how to complete each task in the distribution management process. Only ammunition material managers have the training and knowledge to plan out complex ammunition logistics operations. Material managers must ensure that critical munitions are available for operations. Appropriate risk assessments are in place for hazards above-approved site plans, and the units follow proper regulatory security requirements in the distribution of sensitive ammunition. In comparison, only ammunition managers have the details associated with their specialty independently of other planning efforts. In the end, all sustainment branches provide informed supply planning limits and available decisions to meet the commander’s end state and mission accomplishment.

References:

ATP 4-35 Munitions Operations and Distribution Techniques, September 2014.

ATP 4-42 Materiel Management, Supply, and Field Services Operations, November 2020.

Department of Defense Fiscal Year (FY) 2020 Budget Estimates, Army Justification Book of Procurement of Ammunition, Army, March 2019.

FM 4-01 Army Transportation Operations, April 2014.

Joint Publication 4-0 Joint Logistics, Change 1, 8 May 2019